Module 5.1

Power Transistors and Heat Sinks

- After studying this section, you should be able to:

- Recognise power transistor construction.

- • Understand the need to connect the collector and metal case.

- Understand the relationship between power and temperature in power trainsistors.

- • Power De-rating.

- Understand the need for heat sinks.

- • Methods for choosing heat sinks.

- • Methods for fitting heat sinks.

- Calculate Thermal Resistance requirements for heat sinks.

- • Recognise methods overcoming limitations in heat sinks.

Power Transistors

There is not a clear cut difference between ‘ordinary’ transistors used in voltage amplifiers and power transistors, but generally Power transistors can be categorised as those than can handle more than 1 Ampere of collector (or Drain in the case of FETs) current.

Because power transistors, such as those shown in Fig. 5.1.1 handle larger currents and higher voltages, they have a different construction to small signal devices. They must have low output resistances so that they can deliver large currents to the load, and good junction insulation to withstand high voltages. They must also be able to dissipate heat very quickly so they do not overheat. As most heat is generated at the collector/base junction, the area of this junction is made as large as possible.

Power and Temperature

The maximum power rating of a transistor is largely governed by the temperature of the collector/base junction as can be seen from the power de-rating graph in Fig. 5.1.2. If too much power is dissipated, this junction gets too hot and the transistor will be destroyed, a typical maximum temperature is between 100°C and 150°C, although some devices can withstand higher maximum junction temperatures. The maximum power output available from a power transistor is closely linked to temperature, and above 25°C falls in a linear manner to zero power output as the maximum permissible temperature is reached.

Power De-rating

Fig 5.1.2 Power de-rating Graph for the TIP31

For example, a transistor such as the TIP31 having a quoted maximum power output PTOT of 40W can only handle 40W of power IF the case temperature (slightly less than the junction temperature) is kept below 25°C. The performance of a power transistor is closely dependant on its ability to dissipate the heat generated at the collector base junction.

Minimising the problem of heat is approached in two main ways:

- 1. By operating the transistor in the most efficient way possible, that is by choosing a class of biasing that gives high efficiency and is least wasteful of power.

- 2. By ensuring that the heat produced by the transistor can be removed and effectively transferred to the surrounding air as quickly as possible.

Method 2 above, highlights the importance of the relationship between a power transistor and its heat sink, a device attached to the transistor for the purpose of removing heat. The physical construction of power transistors is therefore designed to maximise the transfer of heat to the heat sink. In addition to the usual collector lead-out wire, the collector of a power transistor, which has a much larger area than that of a small signal transistor, is normally in direct contact with the metal case of the transistor, or a metal mounting pad, which may then be bolted or clipped directly on to a heat-sink. Typical metal cased and metal body power transistors are shown in Fig. 5.1.1

Because power amplifiers generate substantial amounts of heat, which is wasted power, they are made to be as efficient as possible. With voltage amplifiers, low distortion is of greater importance than efficiency, but with power amplifiers, although distortion cannot be ignored, efficiency is vital.

Heat Sinks

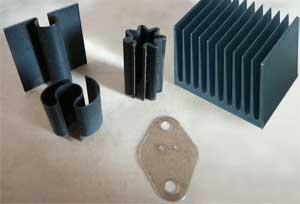

Fig 5.1.3 Heat-sinks

A heat-sink is designed to remove heat from a transistor and dissipate it into the surrounding air as efficiently as possible. Heat-sinks take many different forms, such as finned aluminium or copper sheets or blocks, often painted or anodised matt black to help dissipate heat more quickly. A selection of heat-sinks is illustrated in Fig. 5.1.3.

Good physical contact between the transistor and heat-sink is essential, and a heat transmitting grease (heat-sink compound) is smeared on the contact area before clamping the transistor to the heat-sink.

Where it is necessary to maintain electrical insulation between transistor and heat-sink a mica layer is used between the heat-sink and transistor. Mica has excellent insulation and very good heat conducting properties.

Choosing the Right Heat-sink

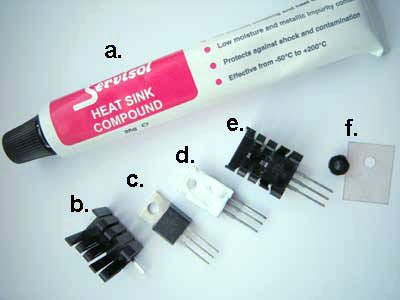

Fig 5.1.4 Fitting a TO220 Heat-sink

Many heat-sinks are available to fit specific transistor package types, (‘package’ refers to the shape and dimensions of the transistor). Fig 5.1.4 shows the various stages in fitting a typical clip on heat-sink.

(a) shows a tube of heat-sink compound.

(b) shows a TO220 clip on heat-sink.

(c) shows a TIP31 transistor, which has a TO220 package type, ready for mounting.

(d) shows the metal body of the transistor smeared with heat-sink compound. This is essential to create efficient heat transfer between the transistor and heat-sink.

(e) shows the transistor fitted to the heat-sink.

(f) shows an alternative method of mounting, used when the metal body of the transistor, (which is usually also the collector terminal), must be insulated from the heat-sink. This example uses a TO220 shaped mica washer, and the transistor is clamped to the heat-sink with a bolt fitted through the small insulating bush.

Typical Rth Calculation for:

- A TIP31 transistor (TO220 package) required to dissipate 5 Watts.

- Maximum Junction Temperature = 150°C

- Ambient (air) temperature = 25°C.

- Thermal resistance between junction and case calculated from power de-rating graph Fig. 5.1.2.

- Rth j-c = (150°C − 25°C) / 40W = 3.125°C/W.

- Max. case temperature when dissipating 5W = 150 − (5 x 3.125) = 134°C (approx).

- Thermal resistance Rth c-hs between case and heat-sink (allowing for mica washer) = 2°C/W.

- Max. heat-sink temperature = 134 - (5 x 2) = 124°C.

- To reach ambient air temperature = 25°C Thermal resistance of heat-sink must be better than (124 − 25) / 5 = 19.8°C/W

- A better choice, to avoid operating the transistor at its maximum permitted temperature, would be to choose a heat-sink with a thermal resistance of about 10 to 15°C/W.

Calculating the Required Thermal Resistance Rth for a Heat-sink

The heat-sink chosen must be able to dissipate heat from the transistor to the surrounding air, quickly enough to prevent the junction temperature of the transistor exceeding its maximum permitted value (usually quoted on the transistor’s data sheet), typically 100 to 150°C.

Each heat-sink has a parameter called its Thermal Resistance (Rth) measured in °C/Watt and the lower the value of Rth the faster heat is dissipated. Other factors affecting heat dissipation include the power (in Watts) being dissipated by the transistor, the efficiency of heat transfer between the internal transistor junction and the transistor case, and the case to the heat-sink.

The difference between the temperature of the heat-sink and the air temperature surrounding the heat-sink (the ambient temperature) must also be taken into account. The main criteria is that the heat-sink should be efficient enough, too efficient is not a problem.

Therefore any heat-sink with a thermal resistance lower or equal to the calculated value should be OK, but to avoid continually running the transistor at, or close to the maximum permitted temperature, which is almost guaranteed to shorten the life of the transistor, it is advisable to use a heat-sink with a lower thermal resistance where possible.

The power de-rating graph for a TIP31 transistor shown in Fig. 5.1.2 illustrates the relationship between the power dissipated by the transistor and the case temperature. When the transistor is dissipating 5W, it can be estimated from the graph that the maximum safe case temperature, for a junction temperature of 150°C would be about 134 to 135°C, confirming the above calculation of max. case temperature.

The TIP31 transistor has a maximum power dissipation PTOT of 40W but it can be seen from the graph in Fig. 5.1.2 that this is only attainable if the case temperature of the transistor can be held at 25°C. The case temperature can only be allowed to rise to 150°C (the same as the maximum junction temperature) if the power dissipation is zero.

Parallel Transistors for High Power Applications

Fig 5.1.5 Power Transistors Connected in Parallel

With high power applications it may be impossible to find a suitable heat-sink for a particular transistor, then one solution would be to use a different power transistor, or different case (package) type if available. Another alternative is to use two or more transistors connected in parallel, sharing the total power between them. This can be a cheaper option than a single very expensive heat-sink.

Thermal Runaway

In many modern circuits power MOSFETs are preferred to BJTs because of the BJTs problem of thermal runaway. This is a process where current flow rises as a natural effect in semiconductors as the temperature of the device increases. This rise in temperature then leads to a further increase in current flow and a subsequent further rise in temperature, until the rise in temperature and current, spirals out of control and the device is destroyed.

When several poorly matched transistors are connected in parallel, the transistor initially passing the most current will get hotter, whilst the others, passing less current get cooler. Therefore the hotter transistor can be in danger of thermal runaway, however BJTs, carefully matched may still be preferable to MOSFETs for some high voltage applications.